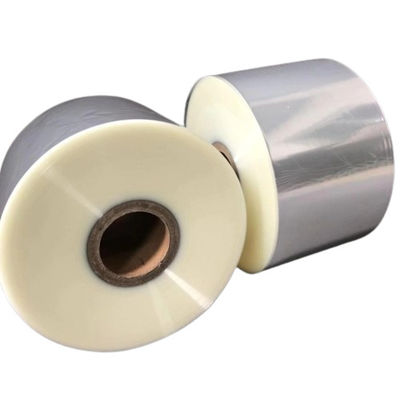

Transparent non heat sealable

|

9, 10, 12, 15, 18, 20, 25, 30

|

Reverse printing lamination, and conversion

|

Transparent non heat sealable

|

15, 18, 20, 25, 30, 35, 40, 50

|

Single/two ply printing, lamination, confectionary packaging, surface printing, inner wrapping, conversion, bags and pouches

|

|

|

9, 10, 12, 15, 18, 20, 25

|

Base film for aluminum metallization for decorative applications and sandwich lamination

|

Metallizable heat sealable

|

|

Base film for aluminum vacuum metallization and higher speed FFS machine

|

|

|

15,18, 20, 25, 30, 35, 40

|

Single/two ply printing lamination, confectionary packaging

|

White pearlized (cavitated)

|

|

Single/two ply printing lamination, confectionary packaging, and high speed packaging

|

|

|

12, 13, 15, 18, 20, 25, 30

|

Reverse printing and/or lamination, and conversion

|

Labels (transparent & pearlized)

|

15,18, 20, 25, 30, 35, 40, 45

|

Suitable for high speed label machine. Wrap-around, real fed and pressure sensitive label

|

Overwrap (transparent & white opaque)

|

|

High speed bundle overwrapping, CD/cassette/paper board boxes overwrap

|

|

|

15, 18, 21, 23, 25, 37, 45, 50

|

Flower overwrap, conversion, textile bags, adhesive tape, photo album

|

|

|

|

Release film application for plywood and decorative lamination

|

Adhesive tapes & textile grade

|

|

Pressure sensitive adhesive tape, and textile bags

|

|

|

|

Cold antifog application for fresh vegetables and fruits, bread, meat, others

|

Base film for Thermal lamination

|

|

Cold fog applicationfor fresh vegetables and fruits, bread, meat, others

|

Base film for Silicone coating

|

18, 20, 25, 30, 35, 40, 45, 50

|

Base film for silicone coating for release liner

|

|

|

|

Antiskid high COF film for packaging application

|

|

|

|

Reverse printing & lamination, release layer in cold seal lamination

|

Oxo-biodegradable (transparent & metallized)

|

|

Printing, lamination and conversion

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!